Anti-sludge flush RESURS

Anti-sludge flush RESURS

Code: 9601

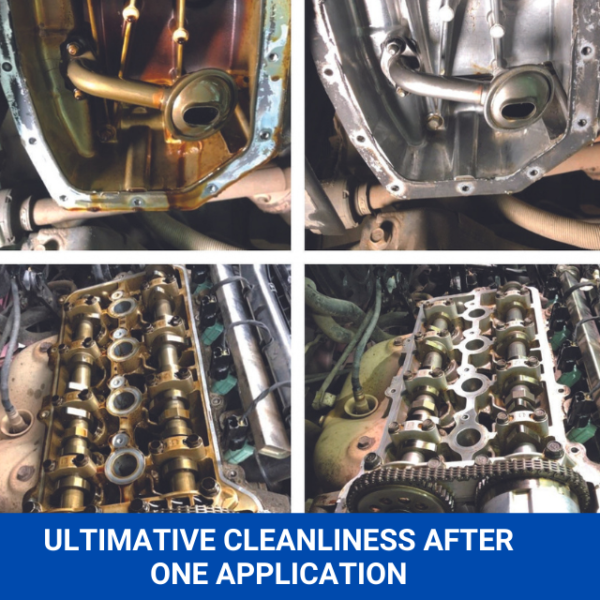

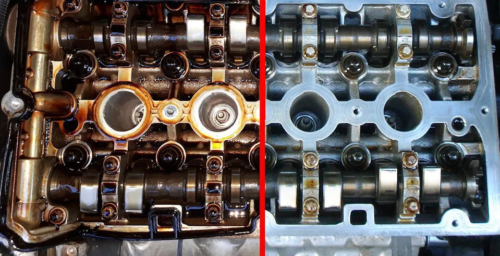

RESURS Anti-sludge flush is a composition that will breathe freshness into your engine. With increasing mileage, degrading oil leaves more and more carbon deposits inside the channels, on oil scraper rings, and engine working cavities. This product effectively dissolves accumulated deposits, transferring them to a suspended state, easily removed when changing the oil.

Engine cleaning without overhaul. Just add in the engine oil!

Packing: 100 ml

Code: 9601

Professional Solution

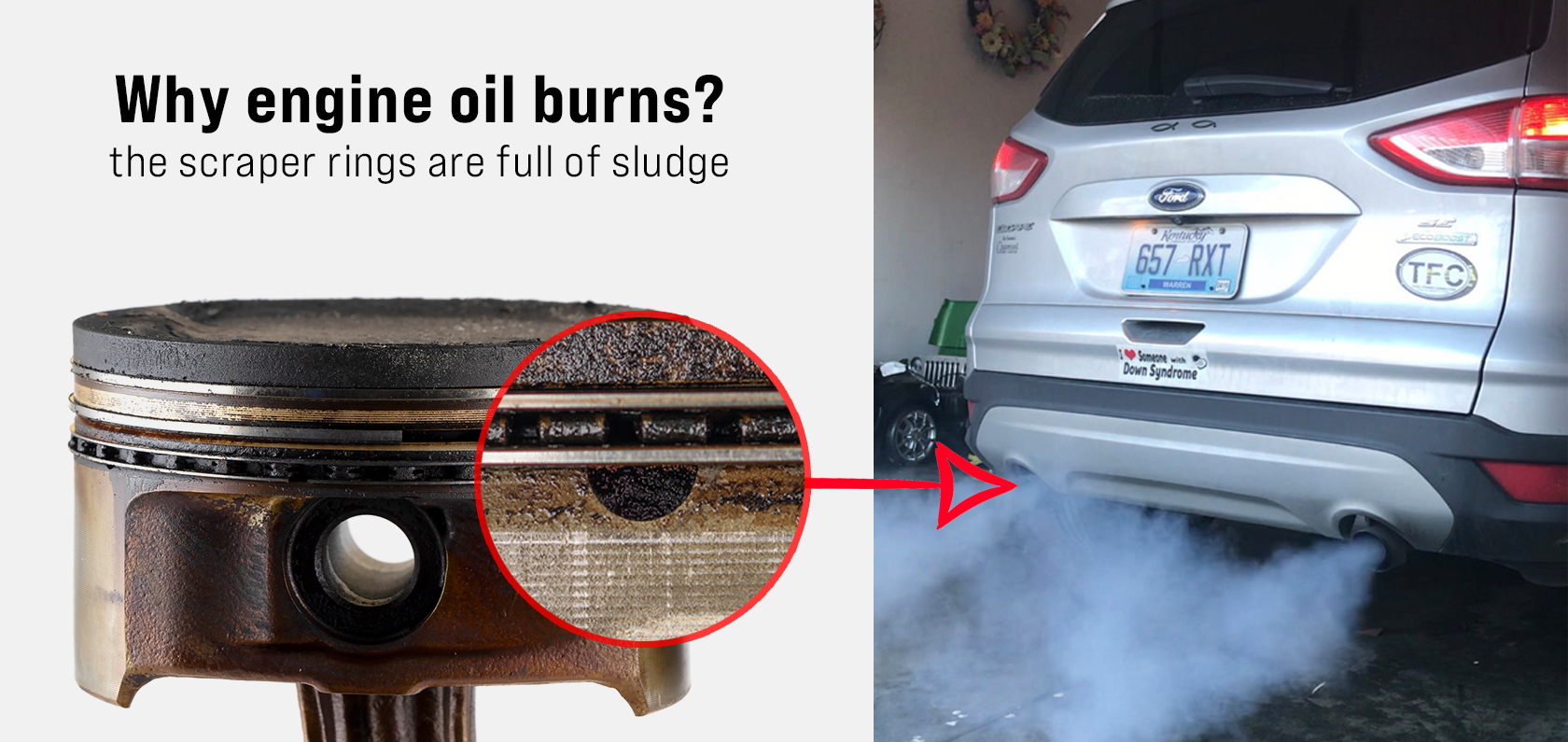

There are a lot of flushes on the market and it is impossible to surprise with another product. However, they all have poor performance in the fight against heavy contamination. They are designed to keep the engine clean. But if problems have already appeared in the form of oil burn, only strong remedies can help. It is Decarboil.

- Reduces oil burning up to 3 times

For deep cleaning of heavily contaminated engines, it is recommended to apply RESURS Decarboil twice, changing the oil each time after a flush cycle.

- Dissolves but not peels off the deposits

- Releases oil scraper rings and channels

Struggles with the cause of oil burn. Contamination of the rings is inevitable – the engine burns fuel, and the combustion products settle on the rings.

Washing away deposits and varnish improves the thermal balance of the engine, which is the basis of its effectiveness and durability