Valve grinding paste Diamond

Valve grinding paste Diamond

For valves of diesel engines.

The paste contains abrasive powder F180 and F320 with an average grain size 50 mkm.

Purpose: for grinding, finishing, and consolidation of valves.

Advantages:

- comfortable bottle packing for easy and equal application on the valve;

- rough and finishing composition in one tube. One tube enough for 100 valves;

- contains components accelerating the time of grinding – average 40 seconds;

- paste remains in contact zone.

A brick-colored paste containing an abrasive close to diamond hardness. It is used for diesel engines.

Consumption – Only 0.2 g per valve.

Grinding time up to 2 min,

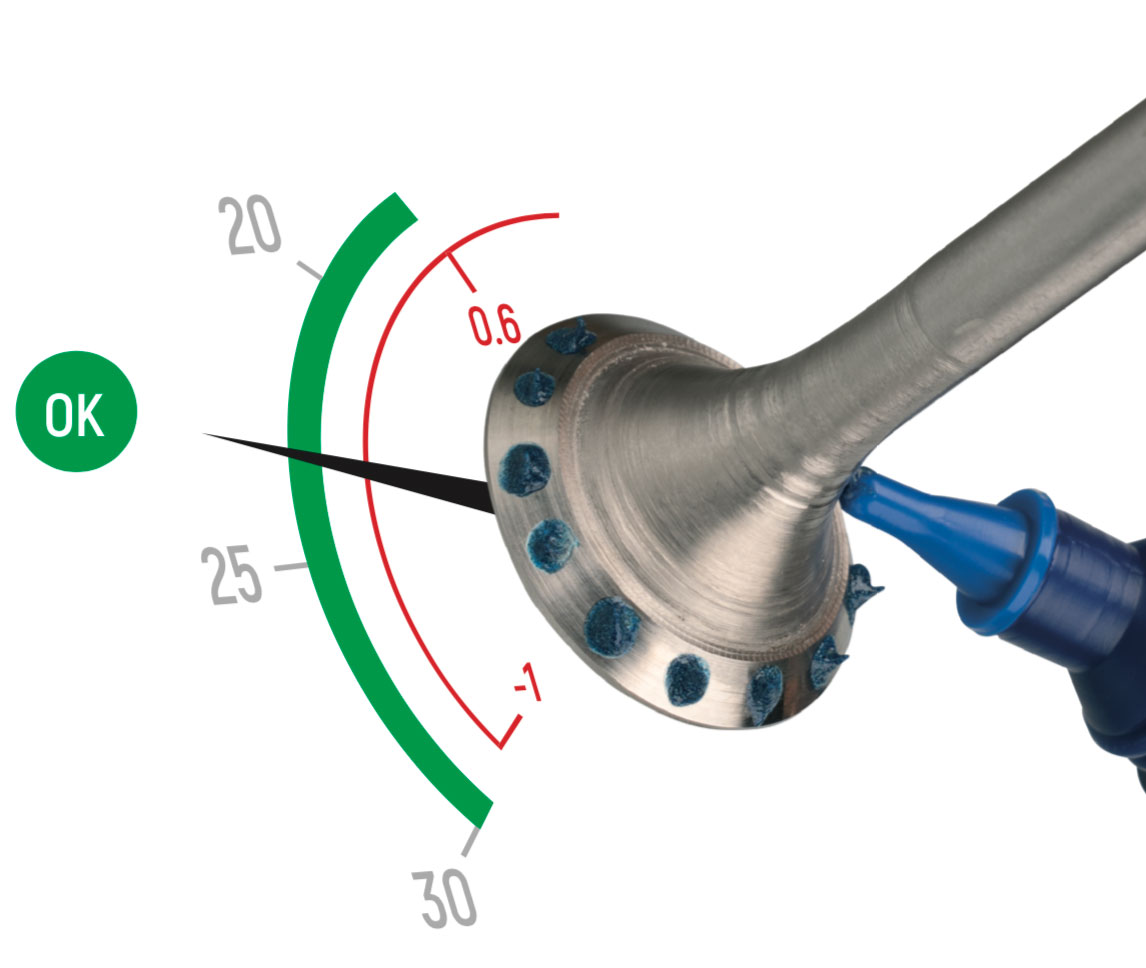

Tightness -0.75 atm

The valves ensure the compression of the combustion chamber. The tightness must be 100%. This can be achieved only by creating a perfect valve-to-seat relief.

How do our grinding pastes help to achieve this result?

Due to its unique composition. 2 in 1 isn’t just a marketing cliché. It is a real functional benefit. While other products are capable of only one-level processing, pastes contain both a rough and a finishing compound in one bottle.

The rough composition of paste Diamond from VMPAUTO – a coarse-grained paste with a grain size of 80 microns – prepares the surface for the next stage of micro-grinding. When the surface roughness reaches 1.2 microns, the finishing composition of the paste comes into action. The finest grain size of 28 µm allows for the perfect valve profile with roughness down to 0.5 µm. Even better than required by ASTM (1 micron). Thus, in 2 minutes the master gets a valve with almost perfect roughness.