8 hours at maximum rpm

Friends. A year ago we started producing oil for two-stroke engines. During this time it has already managed to gain popularity both among professionals who use various gasoline tools in their hard work, and among dacha owners. There are also many who use our oil on their motorcycle equipment.

We have already told you more than once about how our oil for two-stroke engines differs from those on the market. We also compared it with other oils. This time we decided to make a destructive test.

You have probably seen many times on the net, how saws are forced to work at maximum speed until their piston jams. We have planned to do something similar and decided to bring the chainsaw to maximum rpm and let it work for 8 hours. The main purpose of this test, of course, was not to test the chainsaw, but to test our two-stroke oil.

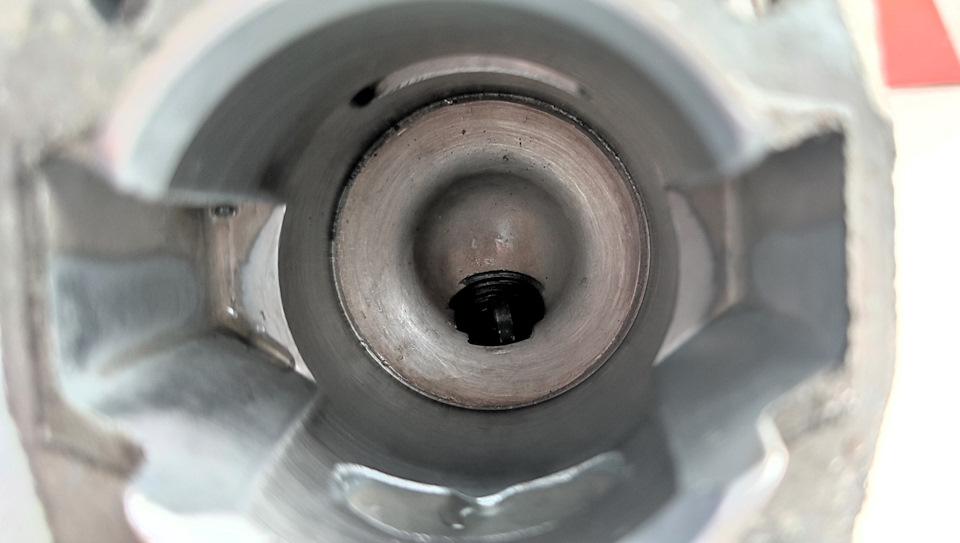

Since the chainsaw we took for testing had already worked a lot of hours on its original oil, we started by disassembling it. The purpose of this measure is to record the condition of the cylinder and at the same time to completely clean the parts from the previous deposits. In the future, this will allow us to assess the changes and the amount of fouling that has formed.

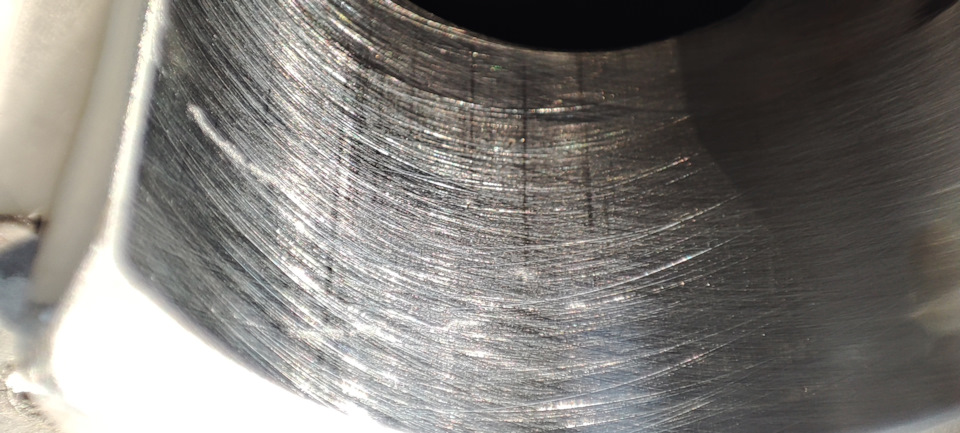

The autopsy showed that the condition of the piston and cylinder walls is almost in perfect condition. Minor scuffs, of course, were both on the cylinder walls and on the piston skirt, but their character spoke not about the lack of lubricating properties of the oil, on which the saw had been operated before, but about the poor quality of air filtration. Sand grains that had gotten in through the filter leaks had left their mark on these parts. After a condition assessment and complete cleaning, the saw was reassembled. For safety reasons, we did not reinstall only the bar and chain.

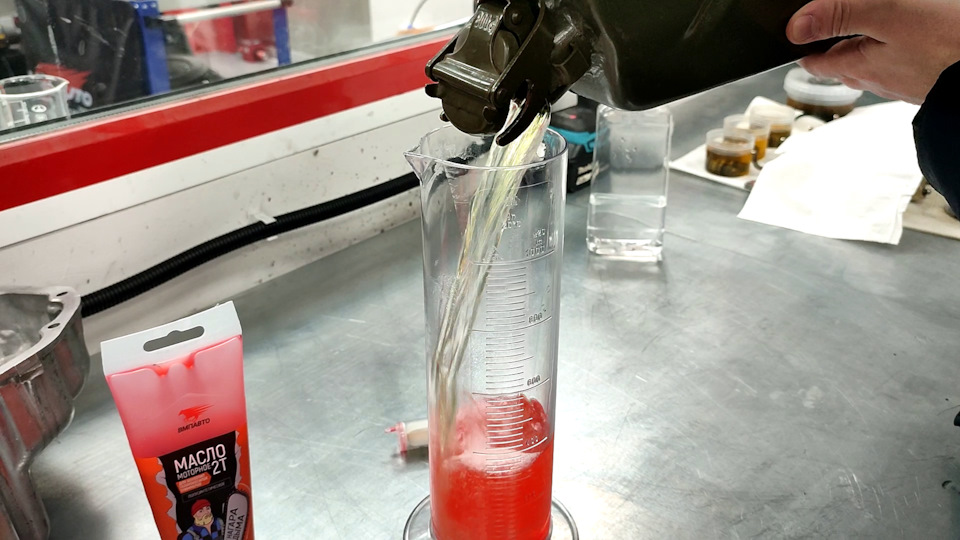

According to the operating instructions, the engine oil for our saw should be diluted in the ratio 1/40. That is, 25 ml of oil per 1 liter of fuel. The oil was taken from the tube with a syringe for accuracy. The fuel mixture was diluted in a measuring cup.

After refueling, the saw was fixed on the frame and the tests began. It must be said that a chainsaw running at 11000 rpm (maximum speed according to the passport) is a pleasure for those who are near it. You can put up with it for the first five minutes, but then your eardrums start to tingle in time with it. After all, it is 110 dB.

Ten minutes later, however, the chainsaw roared with even higher revolutions and stopped. At first it looked like it was finished. But it wasn’t that bad. It just ran out of fuel. After refueling the saw continued to work as if nothing had happened. Only one thing was upsetting. It turned out that you need to refuel its 0.5 liter tank every 10 minutes. That means you have to be on duty around it. I was glad that at least it didn’t smoke.

As a result, the chainsaw worked at maximum speed for the 8 hours allotted to it. During this time it was refueled 48 times. It consumed 24 liters of gasoline and 600 ml of oil. The vibration caused screws to loosen spontaneously and the carburetor settings to go astray. But, one way or another, this test did not lead to any fatal consequences. The saw survived.

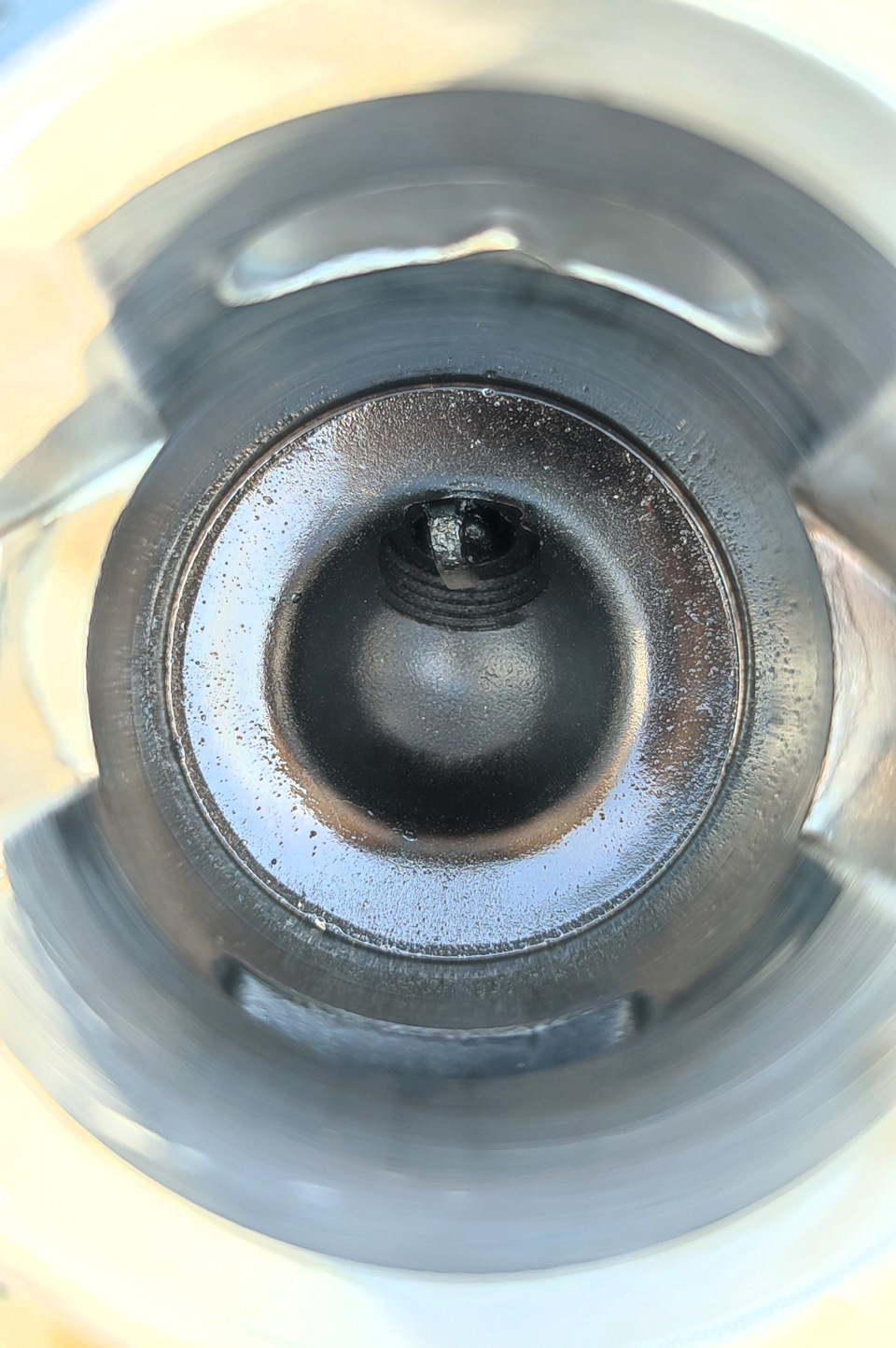

The autopsy confirmed it. The bottom of the piston and the combustion chamber were covered with insignificant soot, which later was practically wiped off with a rag. No serious changes were noticed on the piston skirt and cylinder walls. There were practically no new scuffs. All engine parts had a characteristic oily patina, which indicated good lubricating properties of the fuel-oil mixture.

This is the test. On the one hand very noisy, on the other hand – illustrative.