Equiped with the best research equipment

Friends. Our guests, who visit us both in our production facilities and in the laboratory quite often, are always fascinated by the abundance of laboratory equipment available in our research and development (R&D) department. Today we have decided to show it to you as well. In particular, we will talk about the equipment that has been and is used to create additive packages and engine oils.

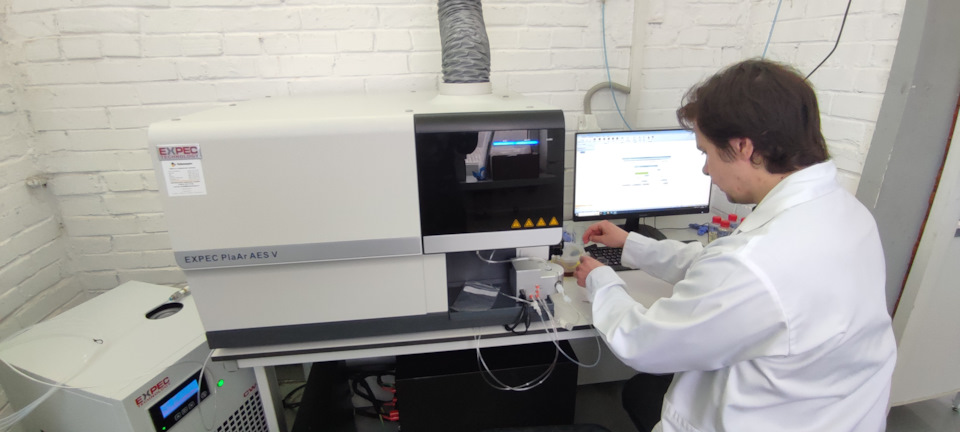

Atomic emission spectrometer

This equipment is designed for elemental analysis of the composition of a wide variety of substances in different states of aggregation. In our case, this apparatus allows determining the elemental analysis of the additive package, finished oil and service oil. It is also used to analyze used oils. The apparatus is very high-tech and very expensive. However, we were not stingy and bought it so that we could quickly examine both promising products and finished samples already analyzed.

The spectrometric method of analysis is based on the measurement of electromagnetic radiation of the optical range emitted by thermally excited free atoms or single-atom ions. It is noteworthy that such a serious process takes only 3-4 minutes, after which the spectrometer produces an oil analysis of 22 elements.

Fourier Infrared Spectrometer

The Infralum FT-02 universal Fourier spectrometer of the mid-infrared range is used to solve various analytical tasks. With its help, types of base oils and antioxidants, dispersant and anti-wear additives are determined. The IR spectrometer is also indispensable in the analysis of oils with mileage, as it allows determining oil nitration and sulfation, the presence of water and fuel.

The equipment works as follows. The oil sample is placed in a special cuvette in the sample compartment. Infrared radiation then excites the vibrational motions of the molecules or their separate fragments and passes through the sample. This causes a weakening of the intensity of the radiation that has passed through the sample. However, absorption does not occur over the entire spectrum of incident radiation, but only at those wavelengths whose energy corresponds to the excitation energies of the vibrations of the molecules under study. Consequently, the wavelengths (or frequencies) at which the maximum absorption of IR radiation is observed may indicate the presence of certain functional groups and other fragments in the sample molecules.

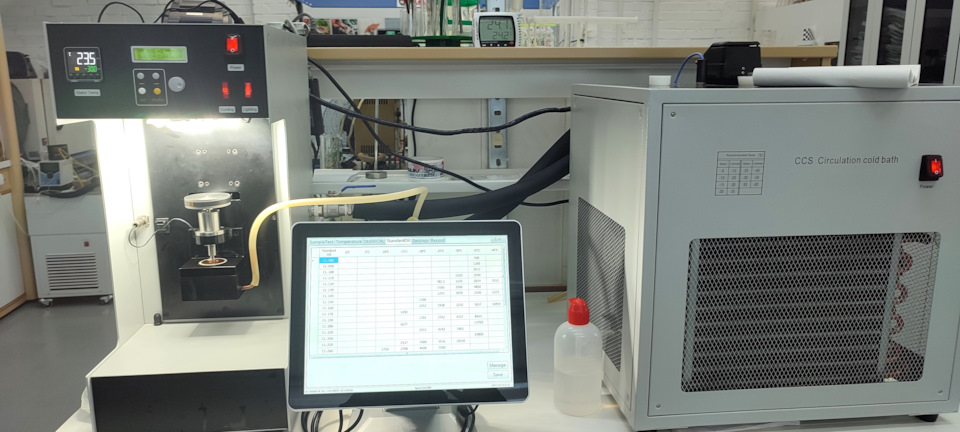

Crankshaft cold start simulator (CCS)

The equipment allows the determination of dynamic viscosity values at low temperature. It is measured using the CCS (Cold Cranking Simulator) according to DIN 51 377 and ASTM D 2602. This parameter indicates how difficult it will be to turn the crankshaft at low temperatures. From the data obtained in this device, the oil is classified according to SAE J300 standards. This parameter is measured in mPa*s.

The operating principle of the device is relatively simple. An oil sample equal to 4 ml is poured into the cell. The refrigerator is turned on. If, for example, 5W oil is investigated, which is to be measured at a temperature of minus 30 °C, the temperature of the cooler is reduced to minus 50 °C. As soon as the temperature reaches the required values, the analysis is started and the cooler begins to cool the cell. Due to the difference between the accumulated temperature and the required temperature, this happens quite quickly: within three minutes. After this time, the rotor starts to rotate in the cell with a certain amount of current. Depending on the rotor speed, the dynamic viscosity of the oil is calculated.

Instrument for determining the pumpability of oils at sub-zero temperatures (MRV)

Pumping capacity is one of the most important indicators when it comes to the low temperature properties of the oil. This device helps to determine whether the thickened oil will be pumped by the oil pump to the lubrication points of the engine. It should be noted that research in this respect is quite time-consuming. For example, it takes about 50 hours to prepare an oil sample for the test at -35°C. Incidentally, the MRV test is so called not by chance. The abbreviation contains the principle of operation of the device. Mini Rotary Viscometr translates as Mini Rotary Viscometer.

Pour point determination device

When studying oils at low temperatures, it is impossible not to mention a parameter such as pour point. For the average consumer, this parameter is not particularly important, since it only indicates at what temperature the oil completely loses its fluidity. In fact, knowing this parameter, it is only possible to determine at what temperature the oil is poured from the drum, and from what temperature it is not even worth trying to pour it. However, this parameter is one of those to be determined according to ASTM D97. A specialized device is also available for this purpose. In addition to the solidification temperature, it also automatically determines the cloud point of the oil. As a rule, it takes about 5 hours to properly cool the oil to a temperature of – 45 °C degrees. As you can see, the test is not very fast either.

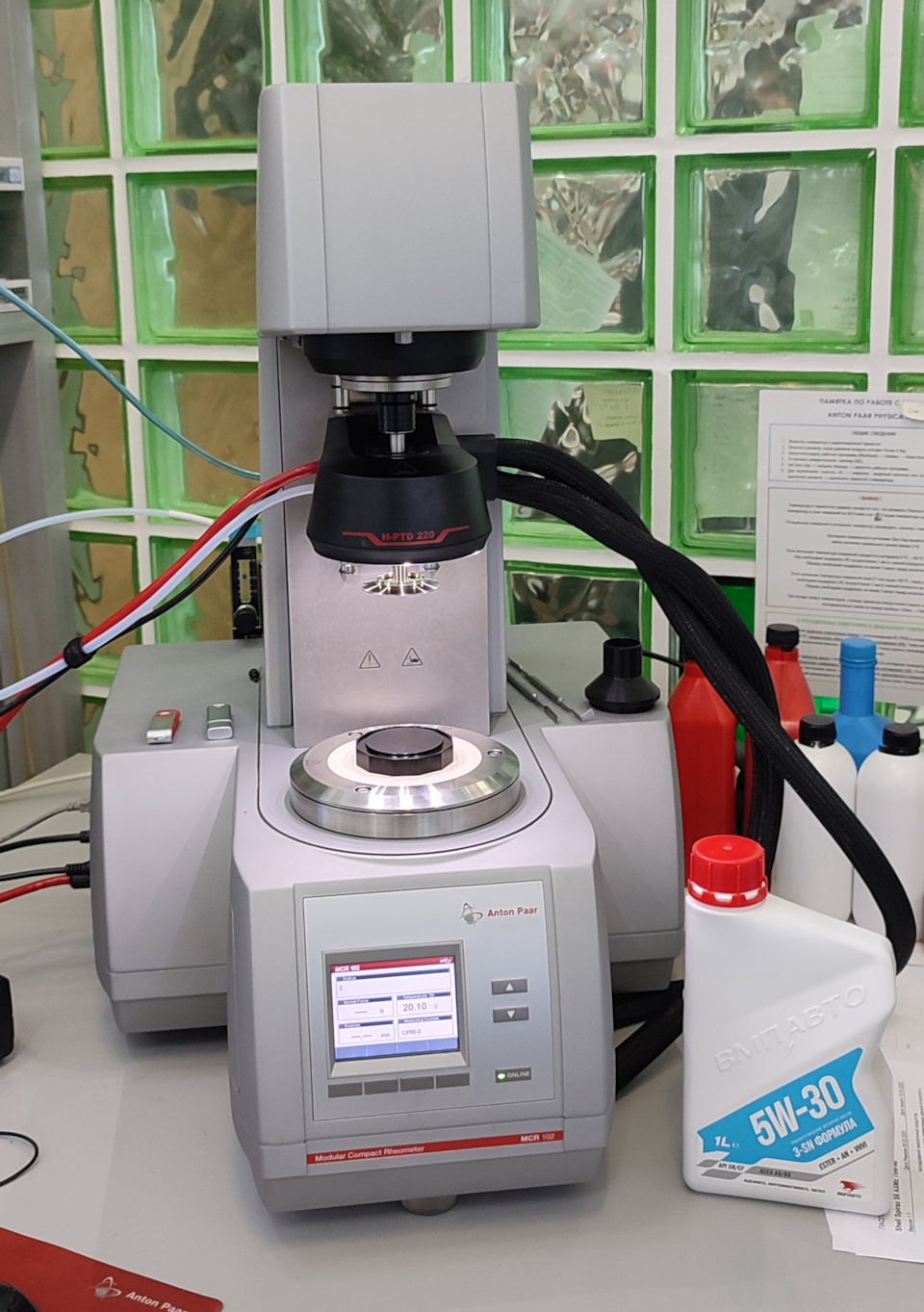

Rheometer Anton Paar MCR 102

cWhen talking about a parameter such as HTHS (High Temperature High Shear), we have repeatedly mentioned the device that allows us to perform these tests. We would like to remind you that the device allows us to perform tests in a wide temperature range, from – 50 ºC to +220 ºC. The oil sample is poured into the cell, after which the measuring system starts rotating. It should be noted that during operation the rotor rests on air bearings only. The HTHS is determined by the moment of rotation between the planes, which are separated by oil with a gap of 0.208 mm.

Stabinger cold properties viscometer Anton Paar SVM 3001

The kinematic viscosity of the oil is an indicator that characterizes the fluidity of the engine oil. El valor de la viscosidad cinemática determina la presión en el sistema de aceite del motor. Naturalmente, a la hora de crear aceites, hay que tener en cuenta este parámetro. Y para tenerlo en cuenta, debe medirse con un equipo adecuado. Y nosotros tenemos ese equipo: es un viscosímetro. Gracias a él, no sólo examinamos los aceites acabados en función de este parámetro, sino que también nos proporcionamos un control cualitativo de entrada de los aceites base. La viscosidad cinemática se mide en mm²/s. The alternative unit of measurement is centistokes (cSt).

In addition to the kinematic viscosity, the device allows the viscosity index to be determined. Se sabe que es una suma de los índices de viscosidad a dos temperaturas: +40 ºC y +100 ºC y caracteriza el cambio de la viscosidad del aceite a partir de la temperatura. The higher the viscosity index, the less the oil viscosity changes as a function of temperature.

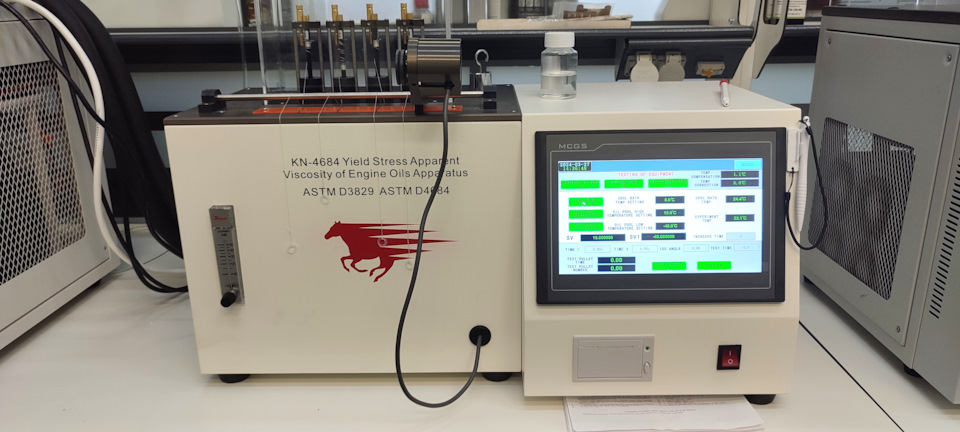

Bosch injector holder

This equipment is used to determine the shear stability of the polymer according to ASTM D7109 and D6278 standards. This test is necessary to check the resistance of the oil to mechanical failure. Thickeners in oils are known to be the first to fail. Therefore, this test is mandatory in the oil development process and in the quality control of the polymers used.

The test is performed as follows. Oil is pumped under the action of a high pressure pump through a Bosch nozzle (as per standard), which is the main polymer destroyer. The oil volume is repeatedly pumped through the nozzle. For gasoline engines it is 30 cycles, for diesel engines it is 90 cycles. The nozzle pressure in this case is 15.5 MPa. Once the test is completed, the oil sample is examined in a viscometer and the difference from the initial values is used to determine the percentage of polymer degradation.

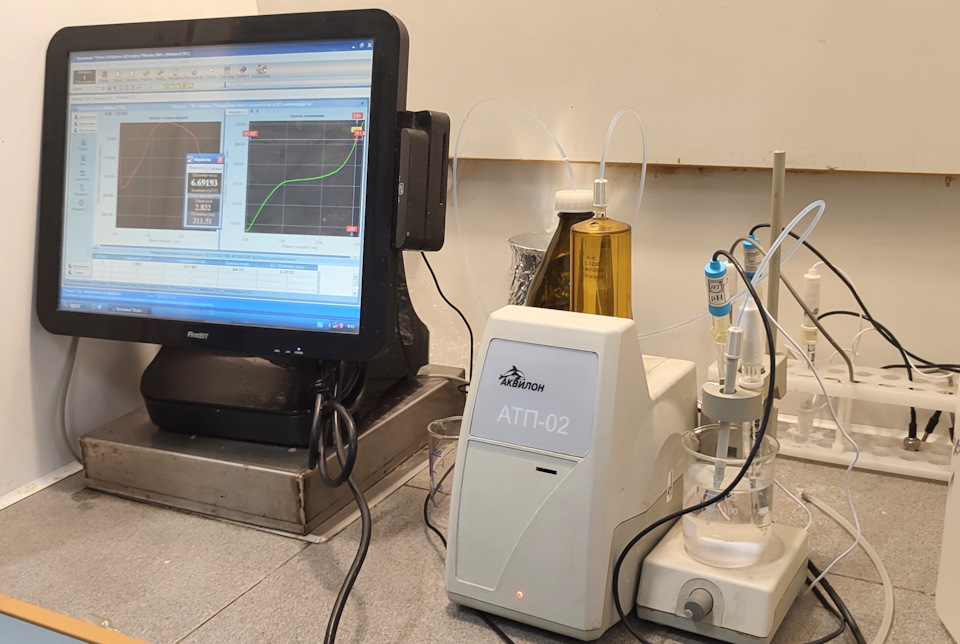

Potentiometric titration instrument

It is well known that the alkalinity index of an oil affects its service life and that the acidity index indicates its degree of aging. Therefore, knowing these values, it is not only possible to predict the service life of a new oil, but also to determine how much it has degraded after a certain mileage. A potentiometric titration instrument helps to determine these values. The potentiometric method consists of measuring the potential of an electrode immersed in the solution being analyzed. In our case, in a solution of oil and solvents.

TWO-LAB-12 flash point analyzer

This parameter characterizes the presence of light boiling fractions in the oil. To obtain this value, our laboratory uses the TVO-LAB-12 apparatus. The equipment allows to determine the flash point in an open crucible according to the Cleveland method.

What does it consist of? An oil sample is poured into an open crucible. The oil is then heated to the expected flash point. As a general rule, good oils have a flash point above 225 °C. Thirty degrees before the expected temperature, the instrument begins to move a gas burner with an open flame source over the oil. At a certain point, the instrument emits a signal indicating that the study is complete. The crucible is automatically covered with a flame arrester and the flash point is displayed on the monitor. The flash is detected by the ionization detector, which is near the oil all this time. At the moment of the flash, the capacitance of the medium changes, whereby the instrument determines that the vapors of the low-viscosity fractions have reached the maximum concentration.

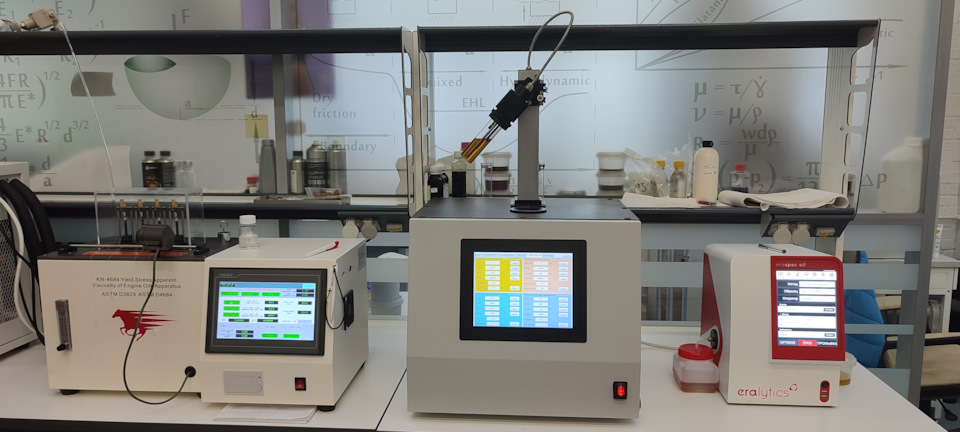

ERASPEC OIL Analyzer

The ERASPEC OIL analyzer is a self-contained portable IR analyzer for rapid analysis and monitoring of the condition of engine oil. The method of investigation is based on the analysis of subsequent samples in comparison with the previously taken fresh oil sample. The device determines contaminants, decomposition products, additive production, as well as calculated parameters such as acid number, alkalinity index and viscosity in a few seconds. The instrument is compact enough to be used in the field.

We hope this information has been of interest to you.