Gasoline engine injector and combustion chamber cleaner concentrate.

Friends. We are pleased to introduce our new product. It is a concentrate composition designed to clean deposits in the fuel system of gasoline engines without removing the injectors from the fuel ramp of the engine.

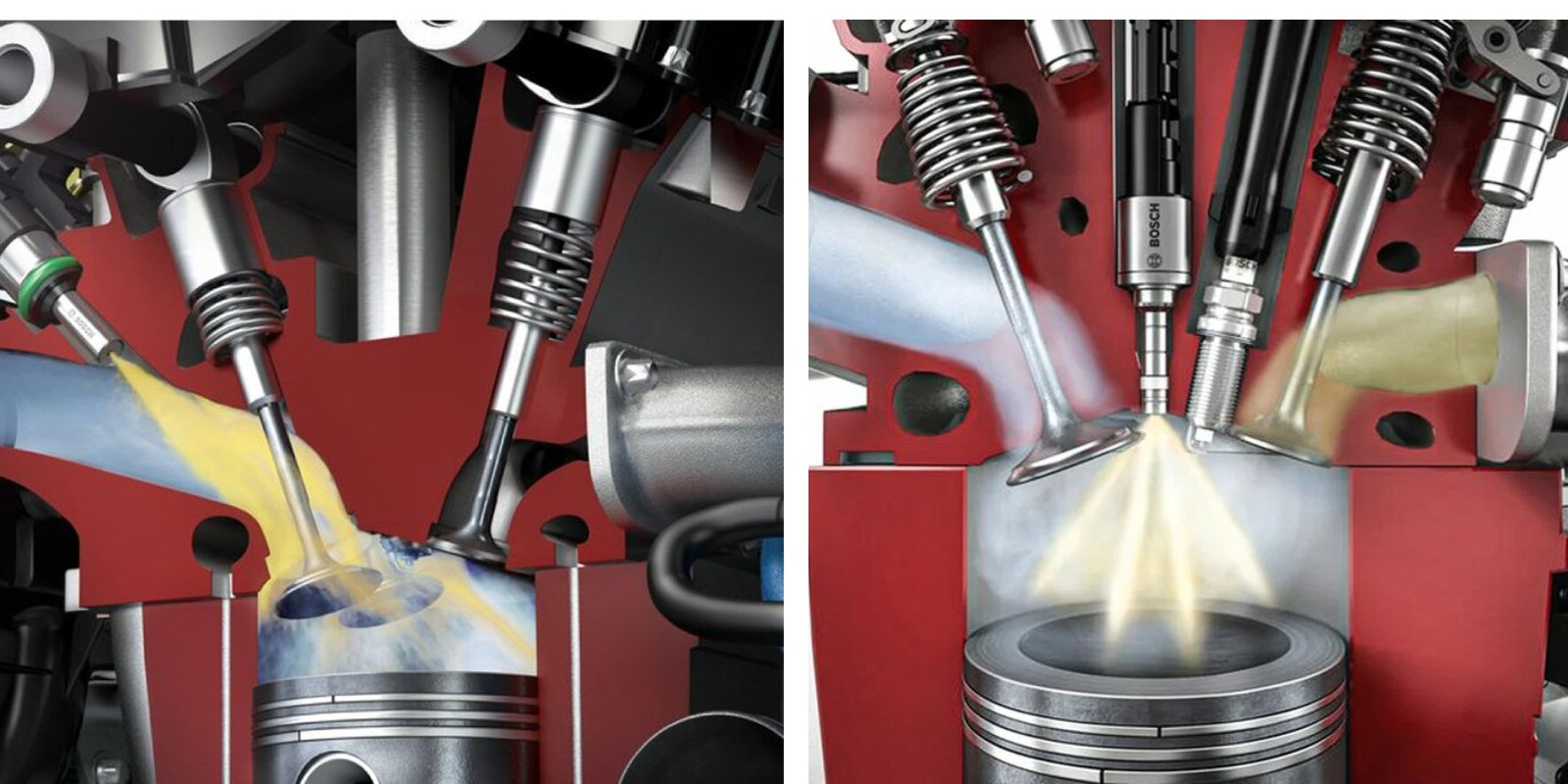

The product is effective for cleaning fuel injectors of intake valves in engines with direct and distributed injection. In addition, the composition also removes carbon deposits from the combustion chamber and pistons.

But why concentrate? The fact is that most of the finished products of this kind already contain gasoline. Usually its share in the product is up to a third of the total volume. We considered it wrong and decided to offer you concentrate. Especially since it is not difficult to dilute it in the correct proportion with gasoline and thus prepare it for work as part of the washing station. All you need is to pour 250 ml of concentrate into a measuring container and add 1 liter of gasoline AI-92 or AI-95 up to the mark. Mix and the cleaner is ready for use.

As a rule, the injector cleaning procedure is performed at a service station. This is the reason why the product has a liter package. The concentrate is enough to clean injectors and combustion chamber on 4 cars with engine capacity up to 2.0 liters. However, if you decide to use it in the garage, this kind of packaging will allow you to clean injectors and combustion chamber more than once. The shelf life of the product is 4 years. Consequently, buying a concentrate cleaner in a liter package, you will provide yourself with a stock of the product for four cleaning, which is recommended to do about once a year. (By voting at the end of the material, you will help to decide whether or not you need a smaller container).

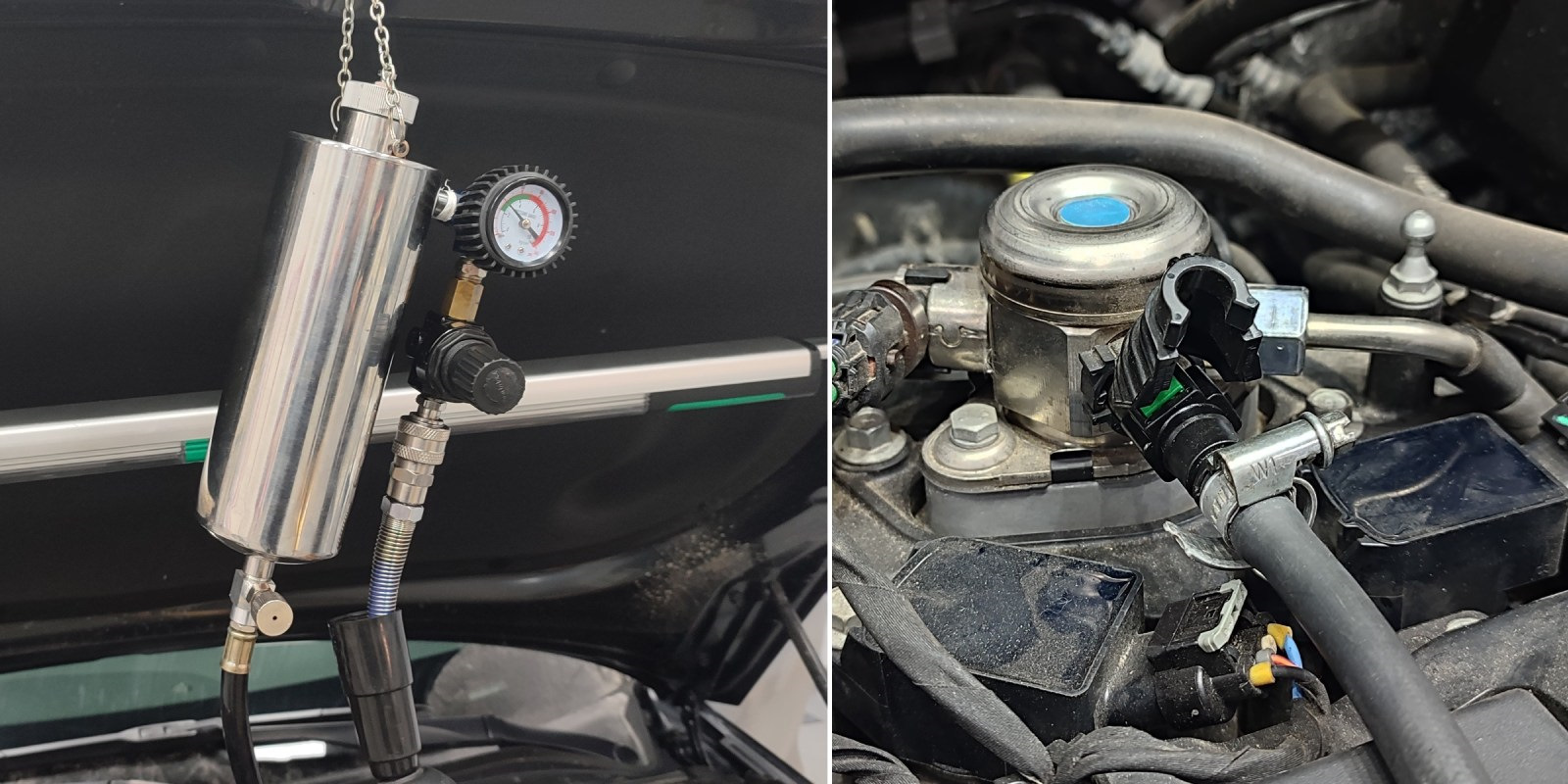

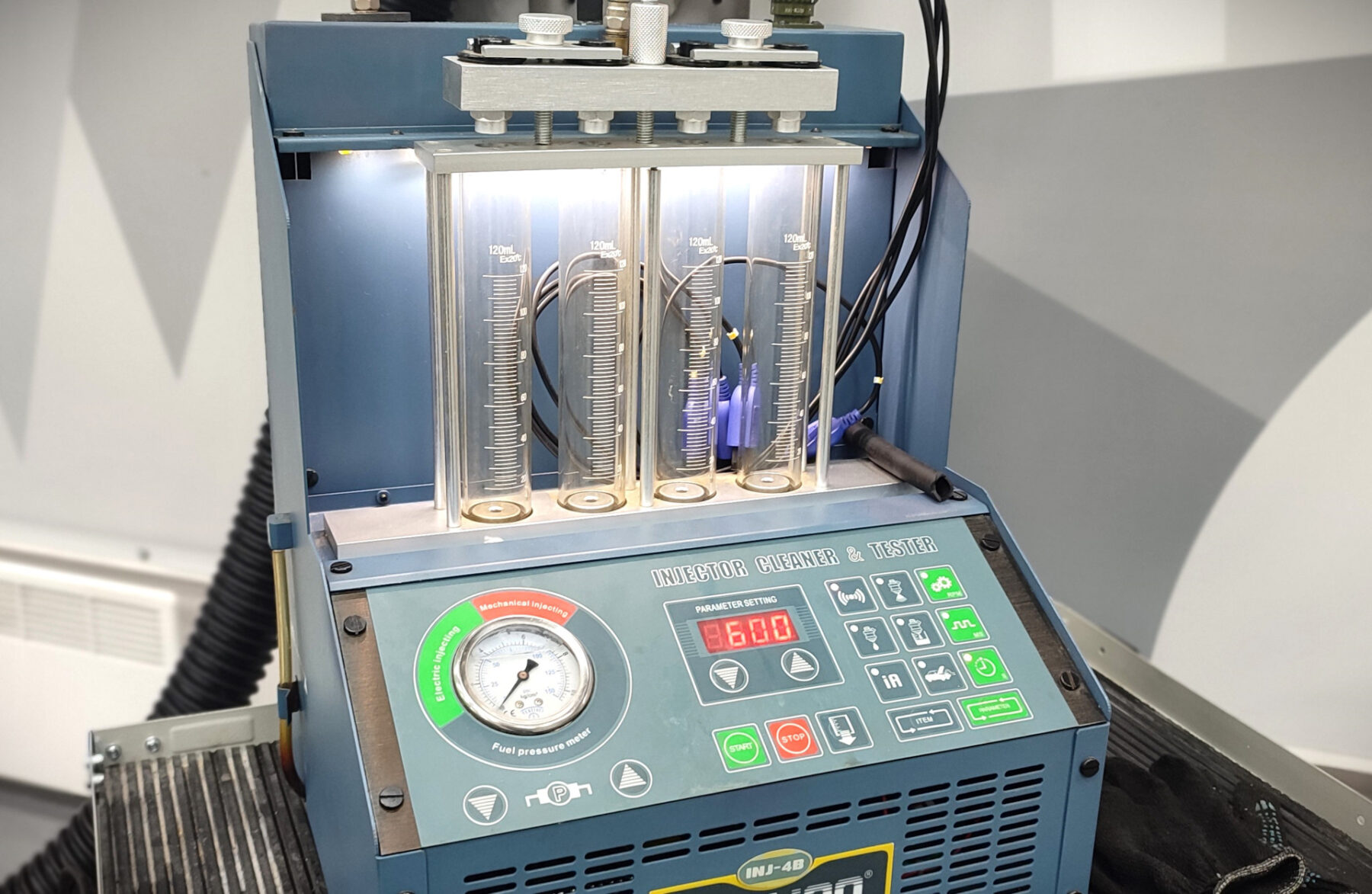

The composition can be used both for cleaning injectors directly on the car with the use of appropriate equipment, and on washing stands.

It is inefficient and uneconomical to use this concentrate to add it to the car tank for further operation in normal mode.

The use of our cleaner as part of the flushing station after diluting the concentrate is no different from the use of similar compositions. The ready mixture is poured into a bulb, which is connected to the fuel ramp of the car.

After checking the flushing station and all connections for leaks, the engine is started for 15 minutes. During this time it runs at idle speed. After this time has elapsed, the engine is stopped and during the next 15 minutes the injectors and combustion chamber are actively cleaned. In parallel with this is the active removal of carbon deposits from the intake valves, if the composition is used on vehicles with distributed injection. After 15 minutes the engine is restarted and runs until the fuel mixture is completely exhausted from the flask.

When cleaning injectors, many manufacturers recommend periodically increasing the engine speed when the engine is running on the remaining mixture. This is also allowed with our product. In this case, the revolutions should be raised for no more than 1-2 minutes, and they should not be higher than 2500 rpm. However, cleaning of injectors and combustion chamber takes place even at idle. As soon as the engine exhausts all the mixture from the flask, the cleaning process can be considered complete. Next, the flushing station is disconnected from the fuel ramp, and the engine is reconnected to the standard fuel supply system.

The degree of contamination of the injectors and combustion chamber varies from vehicle to vehicle. Ideally, before cleaning, an endoscopy should be performed to assess the amount of deposits. However, if this is not possible, it is worth bearing in mind that in cars with direct injection the injectors, as a rule, get fouled much earlier than in cars with distributed injection.

The reason is simple: they are located directly in the combustion chamber, which means that they are in contact with both the fuel mixture and its combustion products. Oil combustion products are also deposited on them, especially if the engine is prone to carbon monoxide by design or due to high mileage. Such injectors should be cleaned more often than the injectors of distributed injection. We recommend doing it once every 30,000 km.

The car owner was satisfied with the result of flushing. The combustion chamber and injectors became cleaner. However, the owner was so impressed by what he saw that he decided to schedule the next flushing for the next maintenance.

Soon our new product will appear on the shelves of stores, and you will be able to appreciate it yourself.