How oils are tested on a bench test

Friends! Not so long ago, in one of the publications, we announced that we were preparing our own package of additives for the production of motor oil. Any motor oil, before reaching the consumer, is subjected to a series of laboratory, bench and full-scale tests. We told you a little about the lab tests of the oil last time. Today we want to tell you what bench tests are.

Oil bench tests are carried out on a car engine. Before testing, the engine is disassembled. They do this for the purpose of visually assessing the amount of deposits on internal engine parts, as well as for checkweighing crankshaft liners, compression rings, and oil scrapers. The level of high and low temperature deposits after the test will determine the oil’s detergency and deposit tendency. The weight of these parts evaluates the oil’s ability to resist wear.

After the control inspection and weighing of the parts, the motor is assembled and installed on the stand. Then, the investigated oil is poured and allowed to run for 40 hours. During operation, to simulate actual operating conditions, the engine is loaded and the speed is also changed from idle to full speed. After 40 hours, the engine is shut down and the first oil sample is taken.

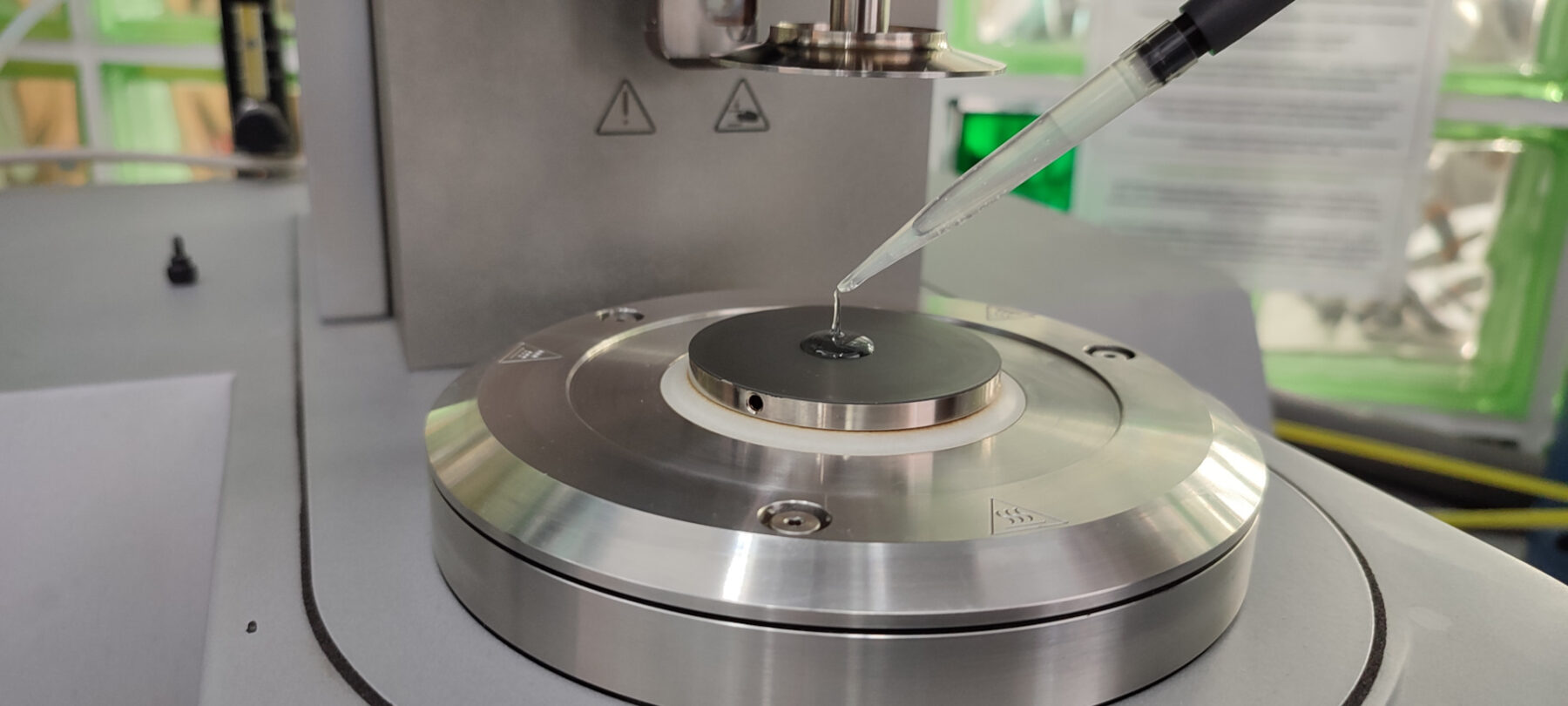

An oil sample is examined in the laboratory for changes in viscosity at low and high temperatures. They determine the viscosity index, the base number, by doing an elemental analysis. An important parameter is the flash point. Naturally, all the results are compared with the data that was obtained in fresh oil before the start of the test. This allows you to track how much the characteristics of the oil change as a result of its operation.

In total, the engine spends 120 hours on the stand, which corresponds to approximately 15,000 km of travel. This is exactly the same mileage that most manufacturers predict for their oil as the maximum allowed. During this time, three oil samples are taken. That is, every 40 hours of operation or 5,000 kilometers. It should be noted that if in the middle of the tests the oil is already quite different from the declared characteristics, its tests are stopped. If all indicators are within tolerances, the oil is tested to the end. After the engine has worked on the dyno for 120 hours, it is disassembled to visually assess varnish deposits, as well as to check the weight of the crankshaft liners and piston rings. Based on the results of the physical and chemical analyses, as well as the results of the inspection and weighing in comparison with the initial data, a conclusion is made about the quality of the oil under study.

Very soon, together with St. Petersburg Polytechnic University, we plan to start testing our oil using this method. In fact, you will be able to follow all the stages of the investigation in real time and, together with us, you will be the first to evaluate the results of the tests. So stay tuned for posts.