New grease synthesis workshop put into operation!

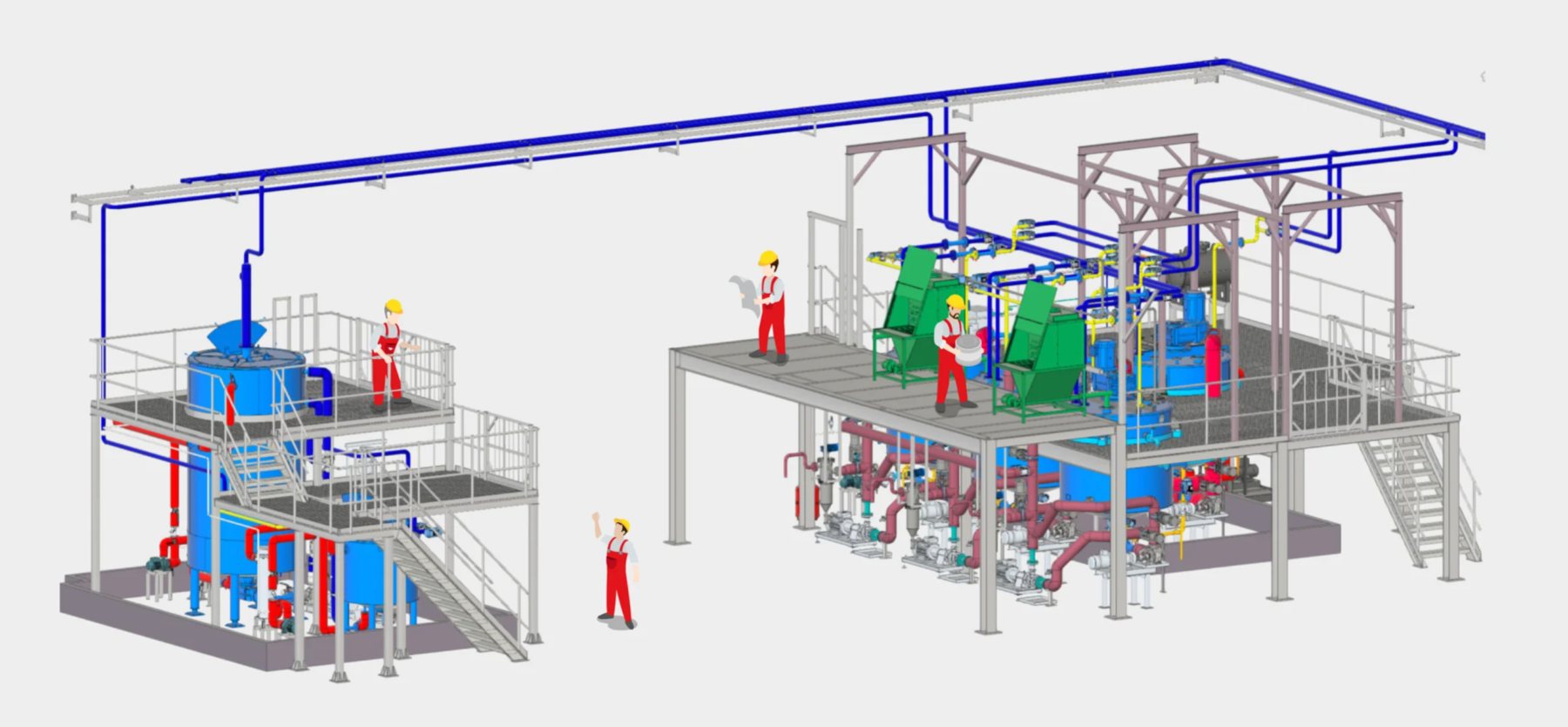

On October 3, 2024, VMPAUTO opened a new workshop “SPS-3”.

Most of the plastic greases produced by our company are obtained in the process of synthesizing thickener, so “SPS” we decipher – synthesis of plastic greases, “3” is a sequential number of the workshop, it is the third such department in our production.

We outlined the SPS-3 project in May 2022, when the number of requests for greases for the mining sector multiplied.

At that time, it became clear that our current capacity was not enough to meet such a large number of requests.

And, naturally, even before the workshop itself was somehow designed, it was clear that we had to start with the purchase of critical equipment, because there are things that are very difficult to acquire, as they are mostly foreign-made.

It took us about a year to purchase the equipment, some of it we ordered in Europe and China, and some we managed to manufacture according to our drawings in Russia.

Toward the end of 2022, the planning of the new workshop began. Initially it was planned to locate the workshop in the same building as the oil workshop on the territory of the existing plant in Kirovsky district of St. Petersburg, but due to the technological peculiarities it was decided to move the workshop to the territory of the new production and warehouse complex in “Industrial Park Maryino”.

It took a few more months to redesign, because the whole work started from scratch, as it was necessary to take into account all the engineering features of the new complex.

It was impossible to start installing the equipment right away, because some of the construction work on the new building had not been completed. As soon as equipment installation became possible, which, roughly speaking, is January 2024, we started building the workshop.

Within the framework of the VMPAUTO conference on October 03, 2024, on the territory of the newest manufacturing and warehouse complex in the “Maryino Technopark”, the grand opening of the new workshop took place.

The event was an important milestone, the guests appreciated the achievements and contribution of VMPAUTO Group to the development of modern industrial lubricants.

At the moment, several syntheses have already taken place in the new workshop, all of them have been successful, possible defects that always arise at start-up have been identified and measures have been taken to eliminate them.

The capacity of the new facility will be two to two and a half thousand tons per year, doubling our capacity to produce greases.

Among the innovations we can mention the modernized system of powder unloading and dosing. There is a special room for localization of work with powders. The possibility of introducing powders through dosers, will allow better control of the recipe and will give the opportunity to influence the process, allowing the output to obtain a product of even higher quality.

The second is the ventilation system. The production of greases is a high-temperature process that requires proper ventilation of the production facilities. The new system will make it possible to remove heat from the working area and prevent the release of waste into the environment.

Various combinations of homogenization of greases during the manufacturing process are implemented in the shop workshop “SPS-3”. Homogenization is a procedure for bringing the composition to a smooth homogeneous mass. The new system will allow to adjust the process depending on the formulation and composition of the product.

It was also possible to improve the cooling system of the finished product, which allows to discharge greases with acceptable temperature for packing.

Double control of dosing by weight, each component is weighed in one way or another.

Very soon the tank farm will start functioning, which will allow to organize storage of base oils in the required volume, about 100 m³.

And, importantly, computers and software that allow you to control the operation of the equipment at every stage.

Two operators are sufficient for the full functioning of the shop, in the standard mode – two syntheses per day.

The new laboratory, fully equipped for the necessary input control of raw materials and output control of finished products, deserves special attention.

Most of the design, assembly and commissioning of the equipment is carried out by our specialists.

All this in order to meet the requirements of the modern market to the greatest extent possible, to create competitive lubricants with outstanding properties.