PAO grease for PTO shaft crosses

Friends. We continue our excursion into the world of specialized lubricants. Last time we told you that we have a grease for ball bearings in our production program. Today we would like to remind you that we also have a specialized grease for PTO shaft crosses.

It has high resistance to oxidation and evaporation, reduces friction and wear, is resistant to water, protects the assembly from corrosion, maintains performance over a wide temperature range from -50°C to +180°C.

As you know, it is very important to use lubricants that do not contain solid particles that can block the needle bearing.

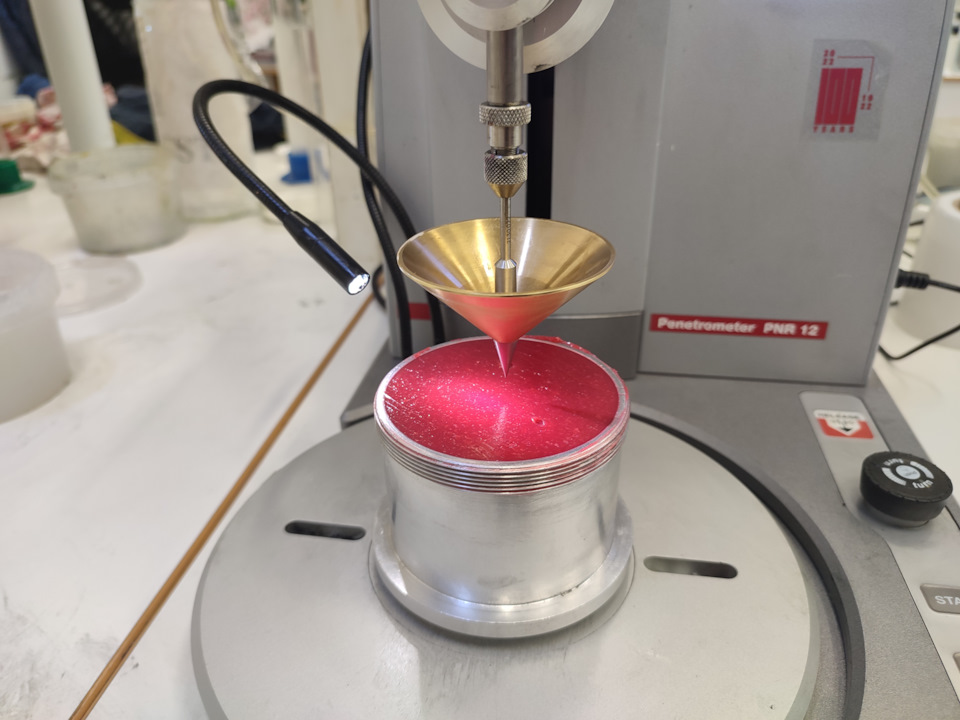

Answer. In spite of partially similar components, these greases are not interchangeable. The NLGI grease for cross-arms has the index “2” and the grease for tripoid joints has the index “1”. The abbreviation NLGI stands for National Lubricating Grease Institute (NLGI). The index assigned by this classification to this or that grease on the basis of penetration indexes reflects its density. Penetration, in turn, is a measure of the penetration of a cone body into a viscous medium, used to characterize the density of substances.

As a reminder, consistency should not be confused with viscosity. Consistency determines the volume retention of the lubricant, while viscosity determines the thickness of the lubricant film.

The viscosity of the base oil of the ball joint grease is 150 cSt, while that of the base oil of the cross pinion grease is 220 cSt.

Based on the above, we can conclude that the lubricant for cross joints is not only thicker than the lubricant for tripoidal ball joints, but also has a different base. As well as a different complex of anti-wear and anti-seize additives, oriented specifically to work in the cross pinion.

Why was this done? The red color allows a better control of the lubrication of the assembly. In addition, the excess grease coming out when filling the assembly with grease by replacing it through the grease nipple gives a better indication of how well the assembly has been serviced.