Checking oils for compatibility with oil seals and gaskets

Friends. Those who follow our publications know that from time to time we tell you how we conduct various laboratory tests of our oil. Today we would like to tell you how oil is tested for compatibility with rubber products.

Engine gaskets, oil seals and gaskets are made of different elastomers.

It is no secret that there are a great number of different kinds of rubber glands, gaskets, seals and spigots in a modern engine. Moreover, some of them may be made of one type of elastomer and some of them may be made of another. It can be polyacrylate ACM rubber, hydrogenated nitrile HNBR-1, fluorocarbon FKM-1, or silicone VMQ-1 rubber. Consequently, when creating an oil, it is necessary to select such a formulation so that not one of these glands or gaskets in contact with oil will not cease to perform its function. And the understanding of whether or not it was possible to maintain the neutrality of the oil to the rubbers should be even before the oil is poured into the engine.

Swollen oil seal. Either the wrong kind of rubber or the oil is not up to standard.

The ASTM standard allows you to do this. The American Society for Testing and Materials is an American international voluntary organization that develops and publishes standards for materials, products, systems and services. Today, ASTM maintains about 12,000 standards and consists of 77 volumes. Virtually all manufacturers that enter the market try to follow these standards.

ASTM D471-16a is also on this extensive list. It is called “Standard Method for Determining the Effects of Liquids on Rubber Properties”. This test method involves procedures for exposing liquids, including motor oil, to test specimens at a specific temperature and time. Factors such as deformation, changes in hardness, mass, volume and dimensions before and after immersion in the test fluid are determined. Laboratory testing to this standard allows for simulation of service conditions through controlled accelerated testing. Note that this method may not provide a direct correlation to the actual performance of the part. It only provides comparative data from which to judge the expected effect of oil on an elastomer.

A variety of elastomers in rolls.

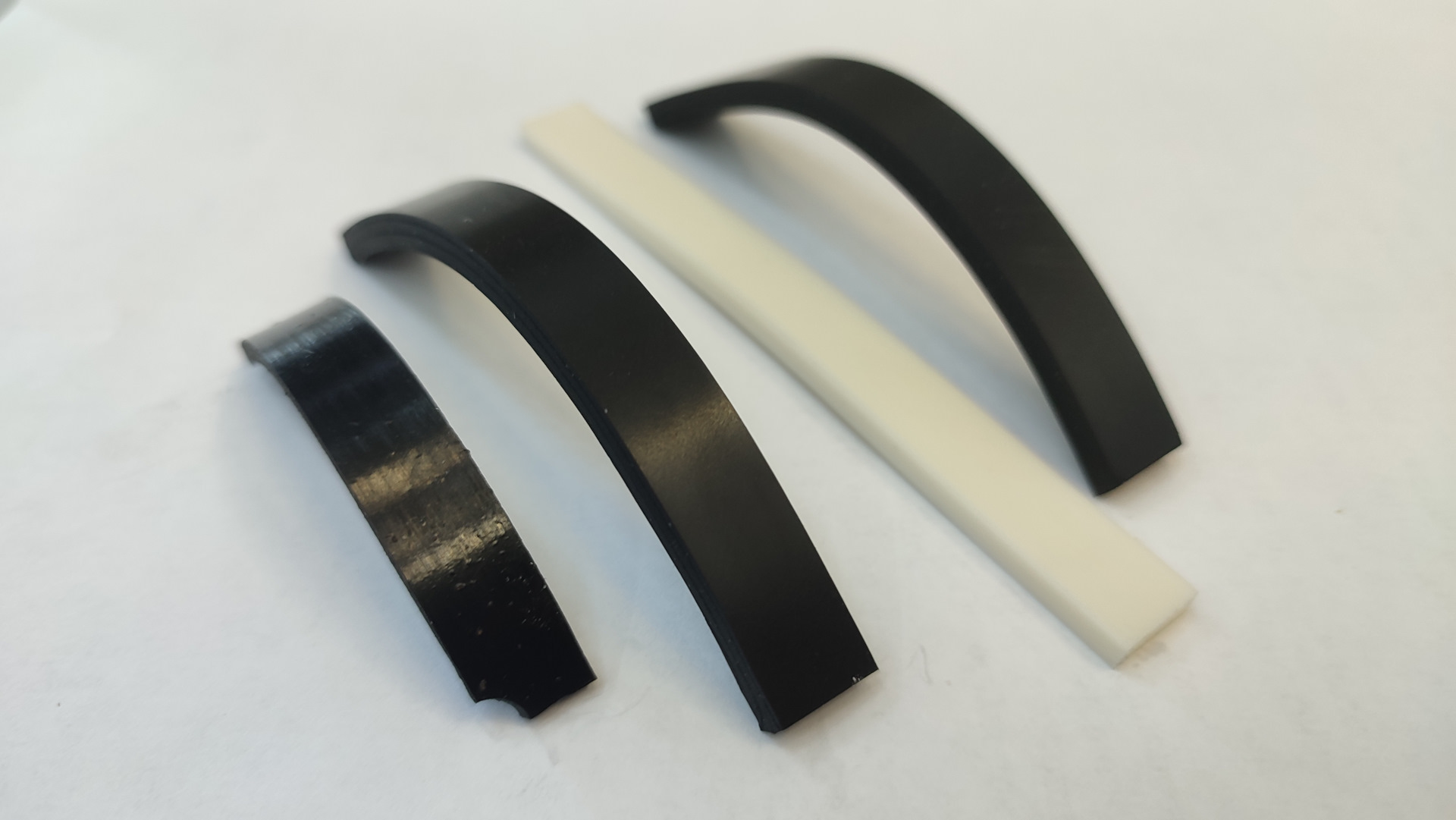

Samples are ready for testing.

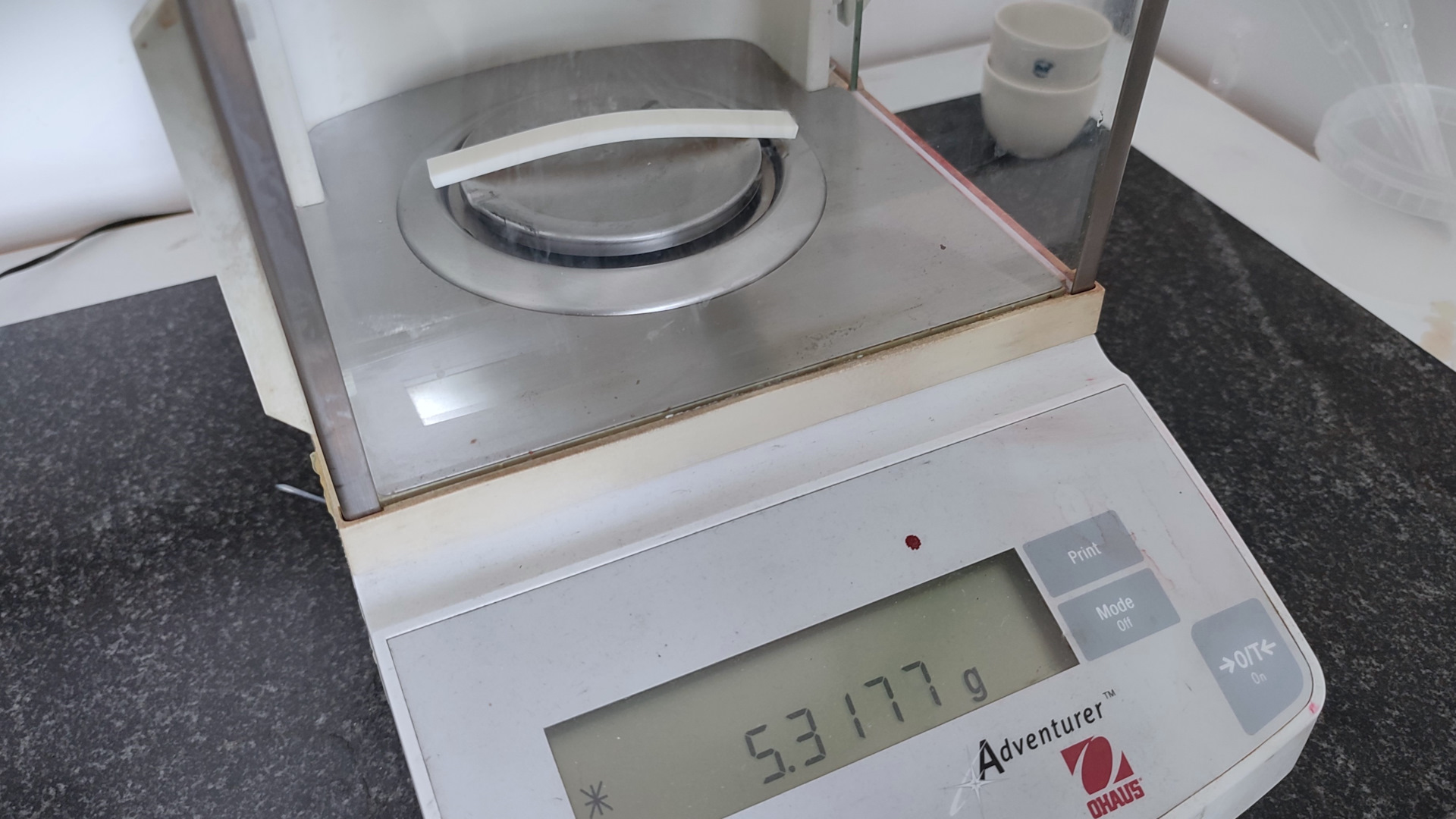

So how are these tests conducted? The first thing to do is to cut identical plates from the rubber samples we mentioned earlier. They are then measured, weighed on analytical scales, and their initial hardness is checked.

Each sample is weighed on analytical scales, the accuracy of which depends even on a whiff of wind.

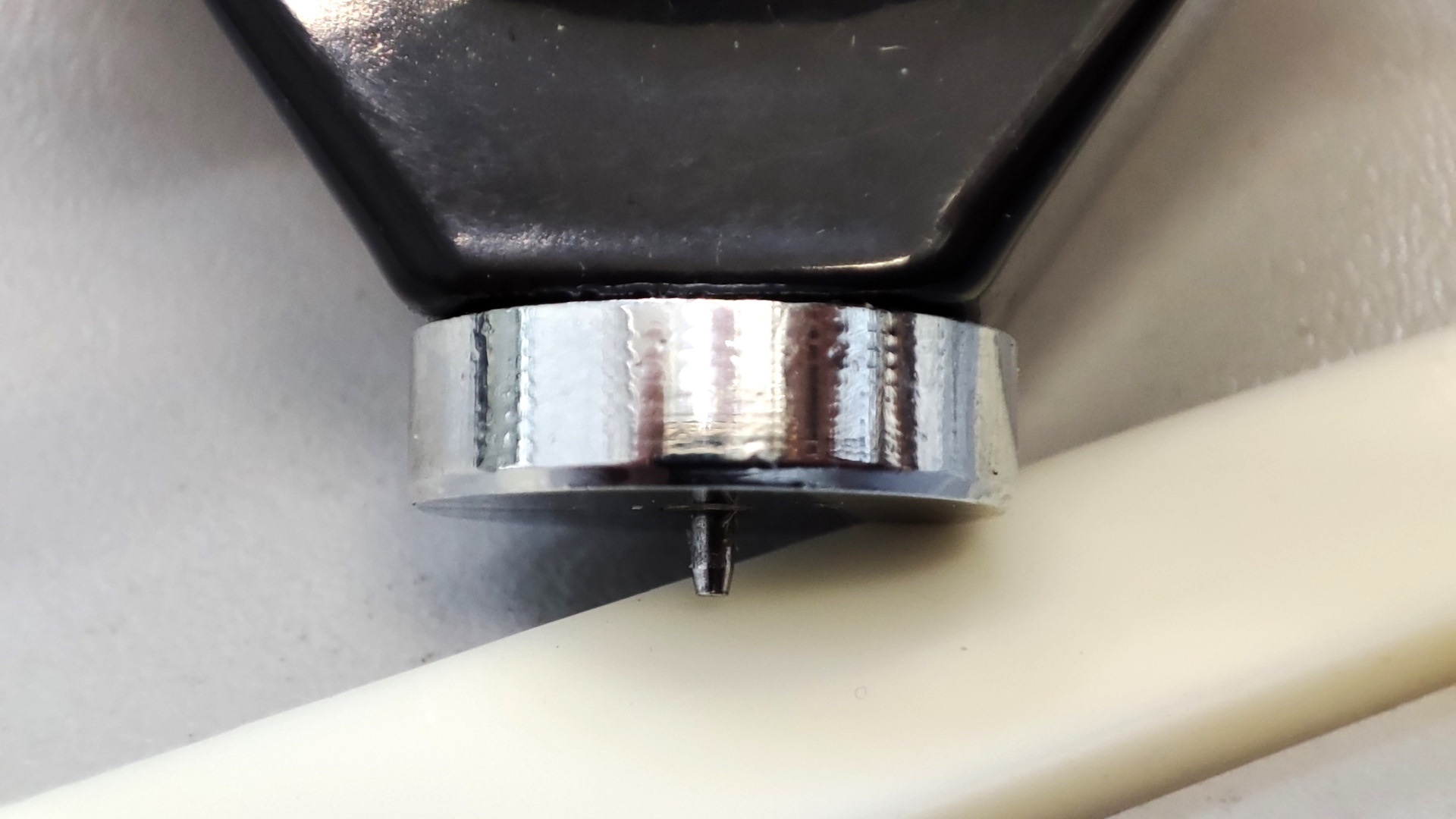

This is how the hardness of the elastomer is measured.

The durometer indenter is pushed into the sample body and the hardness of the sample is measured. The hardness units in Shore are displayed on the screen.

The durometer indenter is pushed into the sample body and the hardness of the sample is measured. The hardness units in Shore are displayed on the screen.

The samples must be completely covered with oil.

Then the containers are placed in a thermo cabinet heated to a temperature of +175ºC for 72 hours. After three days the tubes with elastomer samples are removed from the thermo cabinet.

The rubbers are thawed for three days in a thermal cabinet at a temperature of +175ºC.

Next, the samples are rinsed in acetone, then dried with paper towels and weighed and measured again. The changes are recorded and compared with the original changes. The ASTM, which regulates tolerances for changes in weight, volume and hardness of rubber, is used to determine whether the changes meet the standard or not. If they are within the standard, the oil is safe for RTIs.

Below is a table with data on volume and hardness changes of the samples. In our case, all elastomer samples were more than within tolerances. There are changes, of course, but they did not seriously affect the performance characteristics of the rubbers.

Table of changes in volume and hardness of elastomer samples.

According to the results of research, it can be stated that, using our oil, you can not worry about the condition of gaskets and oil seals. However, this has already been proved by hundreds of hours of tests on bench engines and hundreds of thousands of kilometers of mileage of cars that are operated with our oil.

We hope you found this information useful. Follow the publications.