Premature ignition of the fuel-air mixture. What should I know?

Detonation. Every motorist has probably encountered this phenomenon at least once. Metal ringing from under the hood after a sharp press on the gas pedal has certainly been heard by many. Especially often those who started to accumulate their driving experience on cars with carburetor engines faced the “ringing of fingers”.

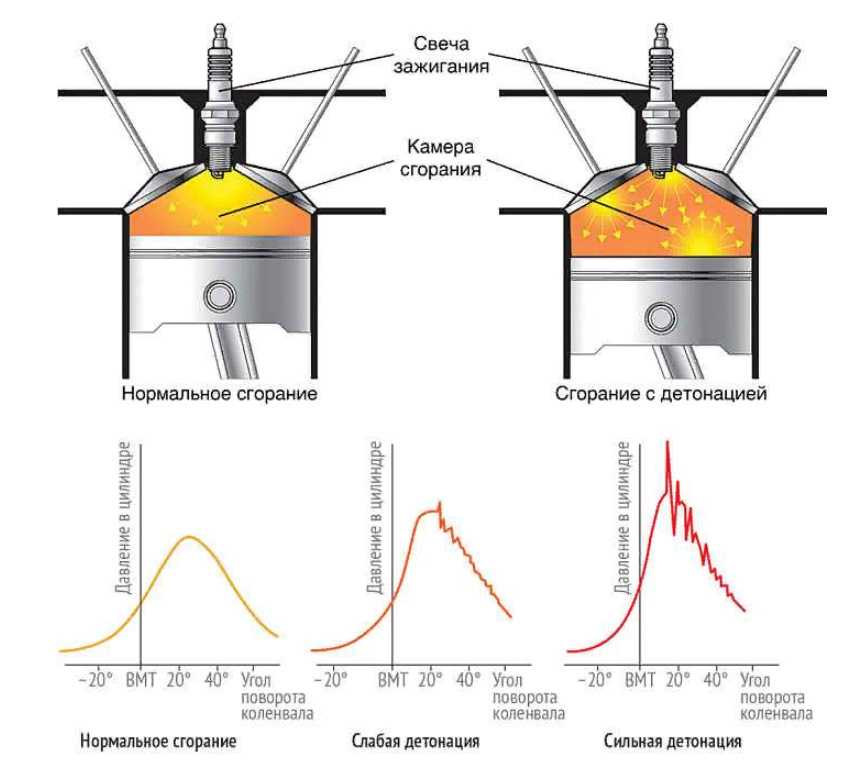

When detonation occurs, the pressure rise in the cylinder is discontinuous.

At that time, this very detonation was primarily associated with low-quality fuel. More precisely, with fuel whose octane number is lower than it should be. After all, the lower it is, the faster the burning speed of gasoline. This means that the explosion of the fuel-air mixture occurs not with a smooth build-up of pressure in the combustion chamber, but much faster. As a consequence, the piston at the compression stroke “gets” on the head much earlier and stronger than it should. To prevent this from happening, such fuel should be ignited later.

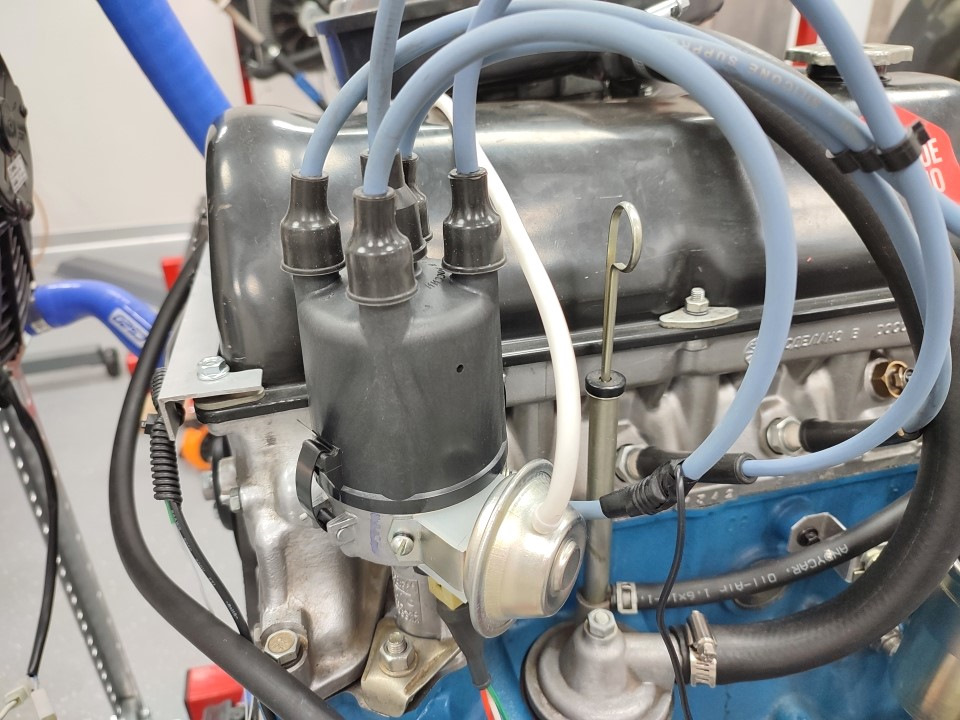

Not every motorist could correctly set the ignition angle by turning the ignition timer and thereby eliminate detonation.

On carburetor engines, experienced motorists forced the spark to “lag” with the help of a trampler. Turning the interrupter-distributor clockwise or counterclockwise, they achieved by ear the moment when, after a sharp opening of the throttle, on a straight gear and at 60 km/h, “fingers tinkled” literally a couple of times. This ignition setting was considered optimal.

The detonation sensor is constantly listening to the engine and adjusting the ignition to avoid detonation.

In modern cars, the electronic engine control unit is already responsible for the timeliness of ignition of the fuel-air mixture. It is assisted by a detonation sensor, which is located on the engine block and constantly listens to the engine. The detonation sensor itself is nothing but a piezoelectric microphone. In case of detonation sounds, it immediately issues a command to the ECU to correct the ignition. In this case, the spark on the plugs occurs later, and detonation passes. But, as a consequence, the process of fuel combustion is no longer optimal and engine power drops. However, it is better to lose power than to lose the engine with prolonged detonation.

By the way. Contrary to popular belief, when detonation occurs, it is not the piston pins that ring. The block rings. Shock waves hitting the cylinder walls at each compression stroke, resulting from combustion of the fuel mixture at supersonic speed, provoke this characteristic sound.

A thick layer of soot on the piston and combustion chamber vault reduces its volume and increases the compression ratio, thus triggering detonation.

In addition to low-octane fuel, soot can also cause detonation in the engine. First, as it builds up on the pistons and the combustion chamber vault, it can significantly reduce the size of the combustion chamber and thereby increase the compression ratio of the engine. And the higher the compression ratio, the more high-octane fuel it needs. And it may happen that one day the engine will have to be converted to a more expensive fuel than it consumed before. Otherwise, detonation will be impossible to get rid of.

If there is a lot of soot, it can start to smolder at high temperatures. This is clearly demonstrated by holding a gas burner close to the soot.

Also, if there is too much soot, it can smolder in the combustion chamber. In this case, it becomes like glowing embers. If the fuel-air mixture hits it, it may ignite spontaneously. So, for example, the coals on the grill flare up from fat dripping from meat. In this case, ignition occurs not only at the wrong time, but also in the wrong place. This kind of spontaneous ignition of the fuel-air mixture is called caliche ignition. And it happens not only because of incorrectly selected spark plugs. Conclusion: You have to fight fouling.

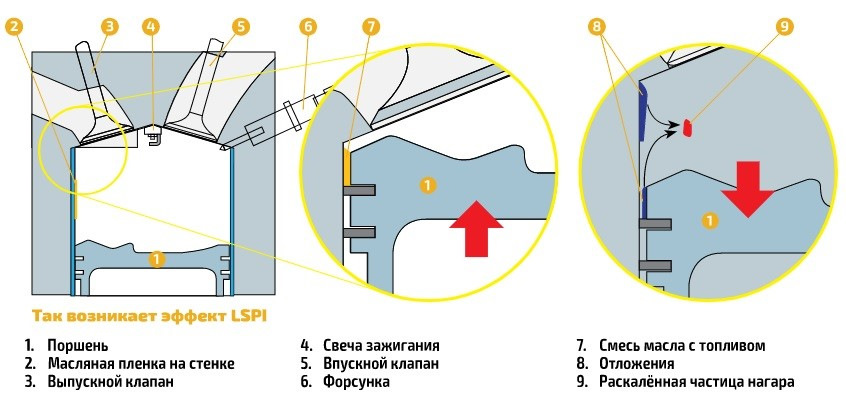

With LSPI, spontaneous ignition of the fuel mixture in the combustion chamber can occur either from a mixture of fuel and oil or from a glowing particle of soot detached from the flame belt.

There is another type of uncontrolled ignition of the fuel mixture. It is called Low Speed Pre-Ignition, which translates as premature ignition at low speed. It is characteristic only for turbocharged engines with direct injection and manifests itself in a sharp transition from low to high speeds. For example, when starting the car dynamically from a traffic light. Due to the high compression ratio and short injection time, part of the fuel does not have time to mix with the air and is localized in the area of the heat belt of the piston. Mixing there with oil, the fuel forms a mixture that ignites much faster than pure fuel. In addition, the fuel can be ignited by particles of red-hot soot that have detached from the flame belt. LSPI is an insidious phenomenon. It can occur at any moment. And unlike ordinary detonation, even a detonation sensor cannot prevent it. Engine destruction is instantaneous.

Broken off part of the piston and fractured baffles between the piston rings. That’s the result of the LSPI.

It should be noted that the study of this phenomenon revealed a certain pattern. It was found that oils with a high calcium content as a detergent (detergent additives) significantly increase the probability of LSPI occurrence. At the same time, reduction of calcium from 2500 ppm to 1250 ppm and introduction of magnesium detergent additives significantly reduces the factor of occurrence of this type of spontaneous ignition to a minimum. And the increase of molybdenum in the oil eliminates this phenomenon altogether. The result of this study was an oil with the SP additive package according to the API classification.

In the near future, our company’s line of motor oils will also be supplemented with SP-package oils. Such oils not only provide modern forced engines with a high level of protection against wear, but also almost completely exclude such phenomenon as LSPI. Follow our publications.