Anti-sludge foam RESURS

Anti-sludge foam RESURS

Code: 8505

Cleanness is the key to reliable engine operation

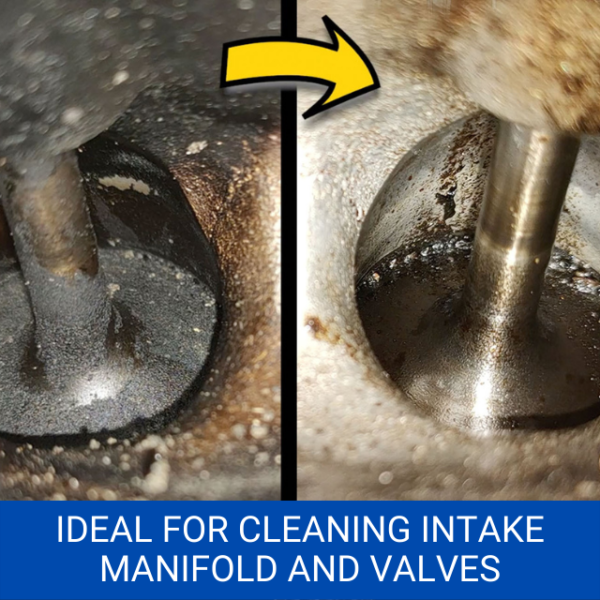

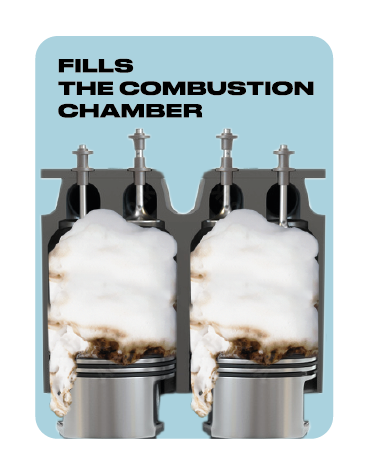

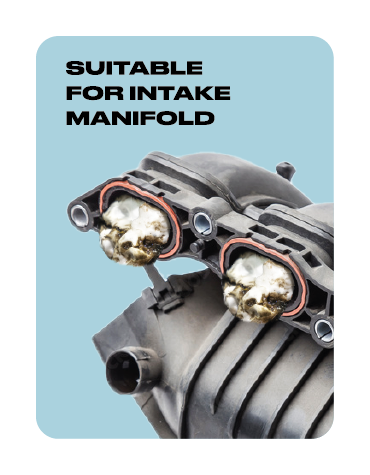

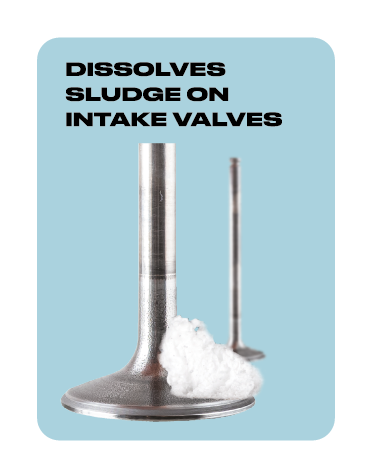

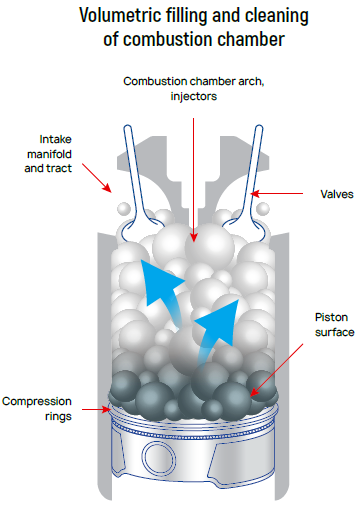

Anti-sludge foam RESURS is designed for professional cleaning of the combustion chamber and removal of varnish deposits without disassembling. Sludge, carbon deposits, varnishes provoke engine wear, reducing its reliability. With an increase in mileage, the possibility of oil waste increases. Anti-sludge foam removes the sludge, varnishes, and deposits that result from this problem. The foam dissolves deposits and removes them.

Packing: 400ml

Code: 8505

The procedure takes 30 minutes and is an alternative to a major overhaul. The product is friendly to metals, plastics, and rubber. One bottle is enough to process one 4-cylinder engine up to 2.5 liters. After treatment, smoke may appear, which disappears within 15-30 minutes.

Can be used to clean the EGR valve, turbocharger, and other aluminum, steel, or cast iron parts. Even the most difficult varnish deposits can not resist the foam RESURS.

How does it work:

When penetrating and covering the surfaces contaminated with sludge, soot, or carbon it starts to react converting the solid particles into gelly and liquid substances which can be extracted easily and burned without damaging engine parts, including filters, exhaust systems, and catalytic converters. Due to the 5x application approach, the solution can clean up to 60% of the contaminated surface in just 30 minutes.